Flexible Packaging Manufacturing Experts

DQ PACK specializes in providing efficient and environmentally friendly flexible packaging manufacturing services, combining advanced technology and strict quality control to meet the diverse needs of customers worldwide.

Advanced Equipment & Sufficient Production Capacity

DQ PACK has a Class 300,000 clean room with a total usable area of 35,000 square meters, equipped with 6 automatic packaging and printing lines, 6 advanced high-speed solvent-free laminating lines, 7 high-speed slitting machines and 20 bag-making lines. These state-of-the-art machines ensure that the bags we supply to our customers are of the highest standards of quality and reliability, meeting the diverse requirements of our customers.

Advanced Equipment for Flexible Packaging Manufacturing

State-of-the-art equipment is the core pillar of our efficient production and high quality assurance,

DQ PACK invests in the world's leading equipment and technology to meet the ever-changing needs of our customers.

DQ PACK invests in the world's leading equipment and technology to meet the ever-changing needs of our customers.

Ink Management System

Precise ink management ensures color consistency and improves print quality and productivity.

High-Speed Printing Machine

Equipped with 10-color high-speed printing capability, supporting high-resolution output to meet diverse customization needs.

Printing Quality Inspection Machine

Adopts advanced inspection technology to monitor printing accuracy and ensure products meet strict quality standards.

Lamination Machine

High-performance material lamination machine that enhances durability and air tightness of packaging to meet the needs of multi-layer structures.

Solventless Lamination

Green solventless lamination technology effectively reduces environmental pollution while ensuring efficient production.

Aging Room

Professional aging test environment verifies the stability and reliability of composite materials to ensure long-lasting product performance.

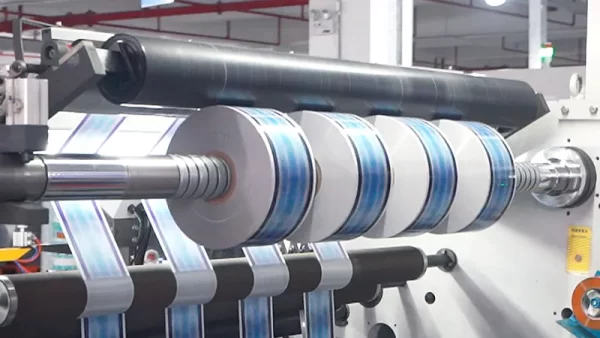

Slitting Machine

Precision slitting machine, providing high precision cutting for packaging materials to meet the subsequent processing size requirements.

Automatic Spout Sealing Machine

Intelligent nozzle bag sealing machine, quickly and accurately sealing, improve packaging efficiency and quality.

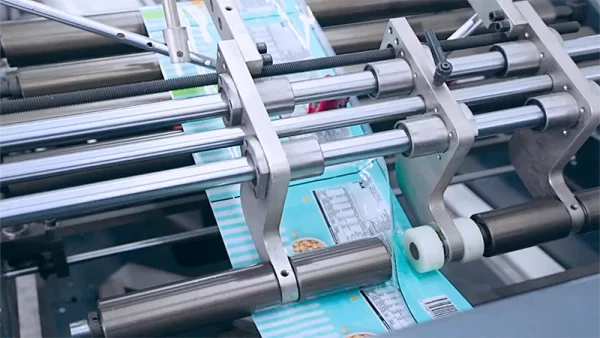

Bag Making

Supporting a variety of bag processing, accurate production of vertical bags, zipper bags, etc., to provide customers with personalized solutions.

Production Process

From raw materials to finished products, one-stop production service

01

Submit Ideas

Submit your needs, share your ideas or provide us with a draft design and our team will develop a customized solution based on your requirements.

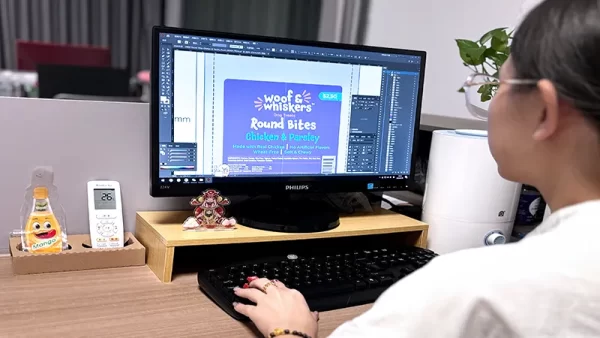

Drawing Design

Our designers will mark the details and color code the design, and then provide the design drawings to the client for confirmation to ensure that every aspect meets expectations.

02

03

Producing Cylinder

High-quality copper cylinders are produced according to the design drawings, and the printing equipment is fully prepared to ensure the efficiency and precision of the production process.

Sample Film Confirming

Provide customers with sample pictures or express physical samples for confirmation to ensure that the sample effect fully meets the needs and expectations of customers.

04

05

Printing

We use advanced equipment for high-quality printing to ensure excellent color performance and strict adherence to product standards and customer requirements.

Laminating

Multi-layer laminating is performed according to customer requirements to enhance the durability and functionality of packaging materials and to meet diversified application scenarios.

06

07

Slitting

Using high-precision slitting equipment, the material is cut into specified sizes to ensure that it meets the production requirements of the subsequent processing stages.

Bag Making

We produce a variety of bag types, including stand-up pouches, nozzle pouches, etc., to meet the individual needs of different customers and market positioning.

08

09

Spout Sealing

Perform nozzle sealing according to customer's requirements to ensure firm sealing and excellent sealing of the package to enhance the practicality and aesthetic appearance of the product.

Quality Inspection

Strict quality inspection process is fully implemented, from materials to finished products, to ensure that each product meets the factory standards and customer satisfaction.

10

Get Started with Your Project!

Get a Catalogue & Quote

Contact us to share your custom packaging requirements and design sketches, and our dedicated packaging experts will get in touch with you promptly.

+86-18125839585dqpack@danqing.netSangpu Er Lu, Dongshanhu Industrial Park,Shaxi Town, Chaoan District, Chaozhou City, Guangdong Province

Warning: file_get_contents(http://ip-api.com/json/209.99.155.65): Failed to open stream: HTTP request failed! HTTP/1.1 429 Too Many Requests in /www/wwwroot/www.packagingofchina.com/wp-content/themes/bricks-child/functions.php on line 164