With today’s competitive marketplace, printed flexible packaging film plays a crucial role in the branding and protection of products. If you’re in the food, beverage, or personal care industry, the right choice of flexible packaging print process will improve your product’s shelf life and performance. So what are the top printing processes and how will they impact your packaging quality? Let us venture into the world of flexible printing packaging companies to learn what different printing processes are, their advantages, and how DQパック can help you with high-quality custom custom-printed flexible packaging.

Key Printing Techniques for Flexible Packaging

Gravure Printing: High-Quality and Durable

Gravure printing is widely followed for printed flexible packages due to its rich color capability and high resolution. It involves cutting the picture into a cylinder to ensure high consistency on huge production runs.

Advantages:

✔ High-resolution prints with rich color depth

✔ Excellent durability, making it ideal for bulk orders

✔ Suitable for various materials, including printed flexible packaging film

Best for: Large-volume orders such as food pouches, coffee bags, and snack packaging

Flexographic Printing: Cost-Effective for High-Speed Production

Flexographic printing is a highly efficient process that uses flexible rubber plates to print ink on packaging films. It is an economical and environmentally friendly option for printing flexible packaging.

Advantages:

✔ Fast production speed with lower setup costs

✔ Suitable for a variety of materials, including biodegradable packaging

✔ Works well for flexible packaging printing machines with water-based inks

Best for: Beverage pouches, resealable snack bags, and large-scale supermarket packaging

Digital Printing: Best for Short Runs & Customization

For those companies looking for digital printing flexible packaging, the process offers high customization with no printing plates required. Digital printing is perfect for small series, promotional seasonal packaging, and variable data printing (e.g., QR codes or batch numbers).

Advantages:

✔ No minimum order quantity—ideal for startups and test markets

✔ Fast turnaround time with minimal waste

✔ High-quality prints with personalization options

Best for: Limited-edition packaging, promotional samples, and premium custom printed flexible packaging

Offset Printing: High Precision for Premium Packaging

Although less common in flexible packaging printing, offset printing offers precise color matching and a high-end finish. It is mostly used for luxury packaging or paper-based flexible materials.

Advantages:

✔ Exceptional print quality with detailed graphics

✔ Best for premium brands that require sharp, vibrant designs

Best for: High-end food packaging, specialty tea and coffee brands

Choosing the Right Flexible Packaging Printing Method for Your Business

When selecting a flexible packaging printing method, consider these key factors:

- Order Volume – Large-scale production benefits from gravure or flexographic printing, while smaller batches work best with digital printing.

- Material Type – Not all printing techniques work on all materials. Discuss with experts to choose the right fit.

- Budget & Lead Time – Digital printing is quick but may cost more per unit; gravure is cost-effective for high-volume orders.

- Customization Needs – If you need custom printed flexible packaging, digital printing allows greater flexibility.

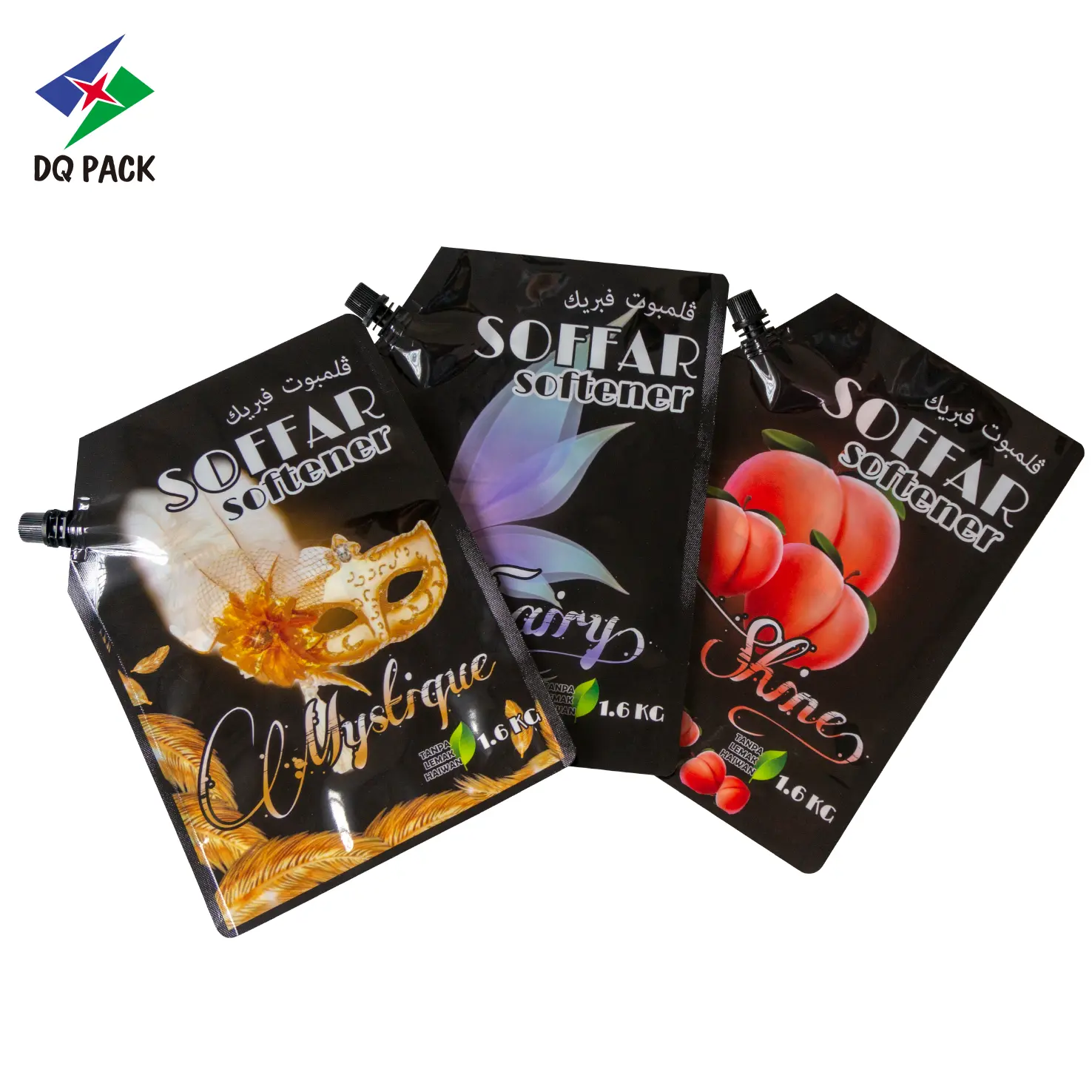

Why Choose DQ PACK for Flexible Packaging Printing?

At DQ PACK, we specialize in printing flexible packaging solutions, offering cutting-edge flexible packaging presses and high-quality printing processes. Here’s why global brands trust us:

- Advanced Printing Technology: We use state-of-the-art gravure-printed flexible packaging solutions. The LUSTER print quality inspection system uses cutting-edge flexible packaging technology with an accuracy of up to 0.1mm² to detect and prevent defects such as streaks, missed prints, splashes, color differences, and dirty prints.

- Eco-friendly Options: Our efficient control of the mixing, storage, and dispensing of water-based and solvent-based inks reduces the environmental impact of waste while maintaining vibrant colors.

- Customizable Solutions: Whether you need unique branding, high-resolution designs, or variable printing, we offer tailored solutions.

- Local Service: With over 30 years of experience, we serve customers in over 120 countries.

- Fast Turnaround and Competitive Pricing: Our streamlined production process ensures fast 7-15 day delivery without compromising on quality.

Final Thoughts: Elevate Your Brand with High-Quality Printed Flexible Packaging

Choosing the right flexible packaging printing technology is the first step to establishing a strong brand and connecting with consumers. As a new business looking for custom printed flexible packaging or an established business looking for large quantity printed flexible packaging film, DQパック possesses the expertise and capabilities to turn your vision into a reality.

Want to elevate your packaging? Contact DQ PACK today for a complimentary consultation and samples!